Logistics technology: ten years after the acquisition of Kiva system, Amazon finally came up with something real

Source / big data digest (id:bigdatadigest)

By /mickey

In march2012, in order to make distribution centers (DCS) as efficient as possible, e-commerce giant Amazon purchased Kiva's robot warehousing business for $775million, and almost immediately incorporated it into the company, starting the warehousing automation process.

Last June, Amazon released the progress of a batch of warehouse automation robots. At that time, many scientific and technological media directly roast that "these are some outdated automated storage machines". Some experts said that these robot technologies announced at that time "are more than two years behind the most advanced technologies".

The warehouse autonomous mobile robot Bert released by Amazon last year was widely roast

After all, after spending US $700million, coupled with the names of technology companies such as Amazon, it is clear that the industry is looking forward to seeing Amazon develop more leading, safer and more efficient robot projects on the basis of the acquisition of the system.

Just last week, 10 full years after the acquisition, Amazon released a batch of warehousing automation systems. From the released videos, the scenes of these projects are more complex, and the automation system is more autonomous and effective. It can replace workers to complete some useful and valuable warehouse tasks, and at least reduce the workload of workers and the possibility of injury to some extent.

Rack moving machine Cart: proteus

Among all the robots released by Amazon, the most eye-catching system is proteus. This robot car is the Amazon Kiva shelf transport robot series. It is intelligent and safe enough to transition from a highly structured environment to a moderately structured environment, which is a huge challenge for any mobile robot.

Proteus is not only the representative of automatic operation, but also emphasizes "human-computer interaction", which can move freely in the environment of human movement. The "eyes" of the robot are set very simply. On the one hand, they are very practical. On the other hand, they also cooperate with sensors and light bars, making the front face of the robot car very cute.

The green light projected by the robot in front of itself is also designed for human interaction, which can let human know an effective way and movement of the robot in an active state.

Amazon said Proteus was the first "completely autonomous" mobile robot that Amazon claimed. From the past experience, it is difficult to integrate robot technology safely into the same physical space as human beings. Amazon said it believed Proteus would change this while maintaining intelligence, security and collaboration.

In the press release, Amazon also said that Proteus uses advanced security, awareness and navigation technologies developed by Amazon to automatically move in Amazon's warehouse facilities. The robot is designed to automatically instruct it to perform work and move around employees - which means it does not need to be confined to a restricted area. Its operation mode can enhance the simple and safe interaction between technology and people - open up a wider range of possible uses to help our employees - such as the lifting and movement of Amazon's gocart, a non automated wheeled transport tool.

Moving gocart in Amazon's warehouse is a major task. Last year, one of Amazon's robots was designed for this purpose. It is called scooter. However, scooter has low availability. This huge mobile system needs to be loaded manually, and can only move several carts to the same place at the same time, which is not friendly to Amazon.

The emergence of Proteus also means that Amazon has broken the R & D of scooter and turned to a new transportation direction - Man-machine collaboration. Proteus looks like one of Amazon's newer Kiva mobile bases, a combination of sensing and intelligence that allows AMR to operate with appropriately trained people in a semi-structured warehouse environment. Its autonomy seems to be achieved through the combination of stereo vision sensors and several planar lidars on the front and side, which is a good combination of safe and effective indoor positioning in an environment with a bunch of reliable static features.

In addition to Proteus, Amazon has also launched some new robot systems.

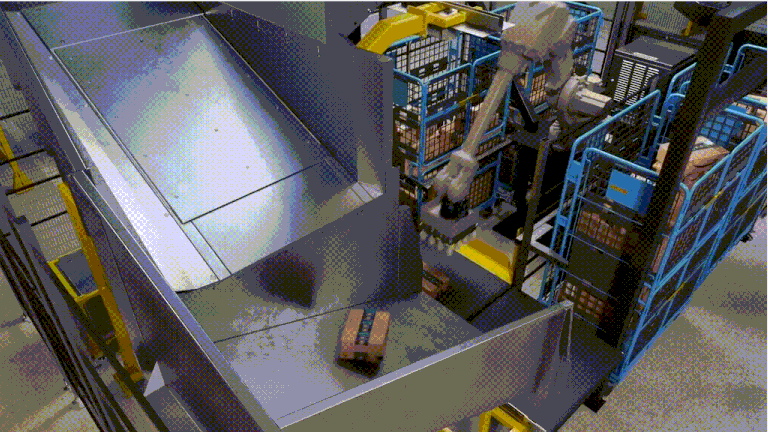

Heavy parcel movement system: Cardinal

Cardinal is a robot work unit. It uses advanced artificial intelligence (AI) and computer vision to flexibly and quickly select a package from a pile of packages, lift the package, read the label, and then accurately put it into gocart and send it to the next station, thereby reducing the workload of warehouse workers and the possibility of injury.

With cardinal, parcel sorting can take place at an earlier stage in the transport process, thereby reducing processing time in the facility. Cardinal converts batch based manual work into continuous automated work, which makes Amazon's transportation business run more smoothly. Currently, it is testing the cardinal prototype for handling packages weighing up to 50 pounds. Amazon said it expected to deploy the technology in the fulfillment center next year.

Scanning system and containerized storage system

Since the outbreak, the e-commerce sector has begun to carry larger packages. Scanning packages at transit stations is one of the most vulnerable scenarios for Amazon employees: transfer employees need to hold a code scanner with one hand and move packages with the other hand. When moving heavy packages, it is easy for employees to be injured accidentally.

The third automated system shown by Amazon is an artificial intelligence scanning function, which can scan packages more easily through computer vision and machine learning technology. Currently, all packages are scanned at each transit station during the journey. In the fulfillment center, this scanning is currently manual - when the items arrive at the workstation, the employee takes out the package from the dustbin, and then uses the manual scanner, the employee finds the barcode and manually scans the items.

The AR ID system replaces the manual scanning process by using a unique camera system of 120 frames per second, providing employees with greater mobility and helping to reduce the risk of injury. Employees can move packages with both hands, instead of handling packages freely with one hand and holding a scanner with the other hand. In this way, the code scanning can be directly replaced by the machine in the future.

Containerized products are another innovation to improve workplace safety. In many Amazon fulfillment centers, employees currently select or store items on mobile shelves in the process of fulfilling customer orders. In order to reduce the need for employees to reach out, bend down or climb a ladder when retrieving items, Amazon has developed another robot system to provide products to employees in a more ergonomic way.

In the field of quickly and reliably selecting random people from objects and putting them into other objects, there is nothing better than the combination of our eyes, brain and hands, but

Amazon said it expected Proteus to start moving shopping carts in specific areas and hoped that it would eventually be able to automate the movement of shopping carts in its warehouses as much as possible. Cardinal is still in prototype form, and Amazon hopes to deploy it in the fulfillment center by next year.

Source / big data digest (id:bigdatadigest)

By /mickey